Ultra Fogger

Fumigation Machine Thermal Fogger

DocumentsIt is equipped with a 10 HP piston engine (US-origin Vanguard) and a 200-liter stainless steel chemical tank. The device can spray 1 hectares in 1 minute. With one tank fill, it can spray minimum 100 hectares within 120 minutes. Without the need for rest, the device can continuously operate for 8 hours with refills.

Description

Description

If you operate in the agricultural sector, please visit our “Agricultural Sector” page. This page contains information specifically aimed at the public health sector.

Thermal fogging machines offer up to 12 times more efficient spraying compared to other spraying devices. These machines perform oil-based spraying, while sprayers apply water-based pesticides. Water-based pesticide droplets are larger and quickly fall to the ground. In contrast, oil-based pesticide droplets are much smaller and can remain suspended in the air for a longer time. Water-based pesticides evaporate faster at ambient temperatures and lose effectiveness, whereas oil-based pesticides are more resistant to evaporation and can reach farther distances.

Spraying 1 decare (1.000 m²) takes only 1 minute with thermal fogging method. This provides significant savings in time and labor costs. Compared to water-based spraying, it allows spraying that is 60 times faster and easier. As to the Ultra Fogger machine, it is the strongest of all thermal fogging technologies, designed for ultra large area spraying: sprays 1 hectares (10.000 m2) in 1 minute.

Thermal fogging machines vaporize the pesticide and spray it as smoke consisting of droplets about 10 microns in size. This method increases the pesticide’s effectiveness by 12 times rather than decreasing it. Thus, contact-effective pesticides spread evenly over large areas and easily come into contact with pests.

It provides guaranteed and definitive control against flying insects such as mosquitoes, Asian tiger mosquitoes, houseflies, stable flies, and biting midges. Due to climate change, the Asian tiger mosquito, characterized by a black body with white stripes, has been observed in our country. These new mosquito species differ from others by transmitting infections to the bite area, causing swelling, itching, and sores approximately 2 cm in size. Additionally, bloodsucking horse flies have begun to appear in large livestock farms due to climate change. These bloodsucking flies, much larger in size than mosquitoes, cause significant harm to living creatures in the environment. By following our company’s recommendations and using correct pesticides and application methods, you can observe these difficult-to-control bloodsucking flies falling from the air to the ground instantly. It is also highly effective for controlling indoor pests such as cockroaches, ticks, fleas, bacteria, and microorganisms.

Application Areas;

✔ Municipalities: Spraying against mosquitoes, houseflies, and other flying insects in parks, gardens, streets, and open areas.

✔ Hotels and Resorts: Pest control to increase comfort and customer satisfaction in accommodation areas.

✔ Forest Camps: Effective control against dense pest populations in nature-surrounded areas.

✔ Housing Complexes and Residential Areas: Maintaining hygiene in common areas and preventing pest spread.

✔ Warehouses and Storage Areas: Protection against harmful pests in food and product storage locations.

✔ Agricultural Fields and Greenhouses: Effective solution against plant pests and flying insects.

✔ Animal Shelters: Preventing pest-borne diseases and maintaining hygiene.

✔ Livestock Farms: Suitable for preventing diseases caused by houseflies.

✔ Festivals and Event Areas: Used for flying insect control in crowded and open spaces.

✔ Industrial and Manufacturing Facilities: Pest control in open or non-production areas.

Advantages;

✔ Licensed by the Ministry of Agriculture and Forestry of Turkey.

✔ Holds Tamtest laboratory test reports.

✔ Certified as domestically produced.

✔ The sprayed smoke has an effective range of at least 200 meters.

✔ Ultra Fogger is the strongest thermal fogging machine designed for ultra large areas.

Capable of spraying 1 hectares (10.000 m²) in 1 minute.

✔ Being domestically produced offers advantages in spare parts availability and service.

✔ Long usage life of at least 10 years provides cost amortization benefits.

✔ Effectively and practically controls difficult pests with smoke, improving quality of life.

Frequently Asked Questions ;

What should be considered when purchasing a spraying machine?

When purchasing a spraying machine, the primary criterion is the uninterrupted continuation of periodic spraying activities. For example, mosquito control is generally carried out in 8-day cycles, and during this period, daily spraying must be done regularly considering the larval stage. Since the exact timing of larval deposition from previous mosquitoes cannot be known, the entire population is controlled by daily spraying for the first 8 days. Then, control is maintained with repeated periodic spraying every 8 days. This approach ensures significant savings in biocidal chemical consumption, effectively controlling the entire population.

However, if the spraying machine frequently breaks down, this routine is disrupted, and spraying activities must be restarted daily from scratch. This causes significant losses in both time and chemical costs.

Therefore, when choosing a spraying machine, instead of focusing solely on price-performance ratio; robust, durable, low-risk of break, simple, and purpose-appropriate machines should be preferred. Additionally, purchasing from manufacturers with a proven track record of easily and promptly supplying spare parts and providing after-sales support will be far more efficient in the long run.

In biocidal control, spraying machines are typically purchased once and used for about 10 years. However, biocidal chemicals must be regularly supplied every season for many years. Therefore, the correct equipment choice directly impacts chemical costs in the long term. To save on chemical use and conduct effective control, machines that can spray chemicals at the micron size most suitable for the target pest, have minimal risk of breakdown, and are made with quality components should be preferred. Such machines provide significant savings in labor, time, and chemical consumption, yielding successful biocidal control results in the long term.

Does it reduce the effectiveness of the pesticide?

No, the sprayed fog is not hot. Thermal fogging machines vaporize oil-based liquids by exposing them to high heat, producing particles around 10 microns in diameter and spraying a white-colored fog. Because the fog particles are so small in micron size, they do not carry or transfer heat. This method does not reduce the effectiveness of the pesticide; instead, it increases it 12-fold. As a result, contact-effective pesticides are evenly distributed over large areas and easily come into contact with pests. For example, with 5 liters of mixture, thermal fogging machines produce approximately 2.39 trillion particles. In the treated area, there is no flying pest left untouched by the fog.

Which types of pesticides can be applied with thermal fogging machines?

This device is compatible with various pesticide formulations. It can apply EC, SC, and powder formulations. EC (Emulsifiable Concentrate) pesticides can mix directly with oil, while other formulations require a combination of oil, water, and pesticide. You can obtain “LP fogging oil,” which is water-miscible, from our company. On the market, there are EC formulation (flowable) pesticides capable of effectively controlling the pests you need to target. Your pesticide preference should prioritize EC formulations; if a suitable solution is not found, only then is it recommended to consider other formulations such as powder or SC.

What type of liquid should be used for the fogging?

The fogging liquid should be either “diesel fuel (mazot),” “LP organic fogging oil that is water-miscible,” or “vegetable glycerin oil.” Use of other types of oils is strictly not recommended.

The oil used as fogging liquid in the thermal fogger must be fluid. Otherwise, thick and non-fluid oils can clog the machine’s hoses and reduce performance. The viscosity of LP water-miscible organic fogging oils is suitable for thermal foggers. However, vegetable glycerin is quite viscous and should be diluted with some water to become fluid before use.

As mentioned earlier, EC (Emulsion Concentrate) insecticides can mix directly with oil. We recommend prioritizing EC formulations for thermal fogging machines. If no EC formulation is available, SC (Suspension Concentrate) and powder formulations can be used as secondary options.

EC insecticides mix with oil directly without water. However, if SC or powder insecticides are used, a certain amount of water must be added to dissolve the insecticide properly. Note that not every oil accepts water: for instance olive oil does not mix with water, just like diesel and water do not mix.

EC (Emulsifiable Concentrate) pesticides can mix directly with oil without water. However, if SC (Suspension Concentrate) or powder formulations are to be used, a small amount of water must be added to allow the pesticide to become properly concentrated. It should be noted that not all oils accept water: for example, olive oil does not mix with water, just as diesel fuel does not.

If an operator prepares a mixture of “150 L olive oil + 45 L water + 5 kg powder pesticide” in a machine with a 200-liter spraying tank, the spraying will not be effective. The liquids will not mix homogeneously: the powder pesticide and water settle at the bottom of the tank, while the olive oil remains at the top. For SC and powder pesticide applications, “vegetable glycerin” or organic oils compatible with LP water should be used.

Examples of proper mixtures:

195 L Diesel + 5 L EC insecticide

140 L organic misting oil compatible with LP water + 55 L Water + 5 L SC insecticide

140 L organic misting oil compatible with LP water + 55 L Water + 5 kg powder insecticide

140 L vegetable glycerin oil + 55 L Water + 5 L SC insecticide

140 L vegetable glycerin oil + 55 L Water + 5 kg powder insecticide

Before use, the oil, water, and insecticide mixture should be tested in a 5-liter transparent container. Let it sit for 15 minutes. If the mixture remains homogeneous, it can be poured into the fogger tank. If the liquids separate into layers inside the transparent container, this indicates a failed mixture and it should not be used in the fogger. With such a failed mixture, the machine will first spray the insecticide-rich water, then later only oil, resulting in ineffective fogging.

In short, always ensure the mixture is homogeneous before starting fogging operation.

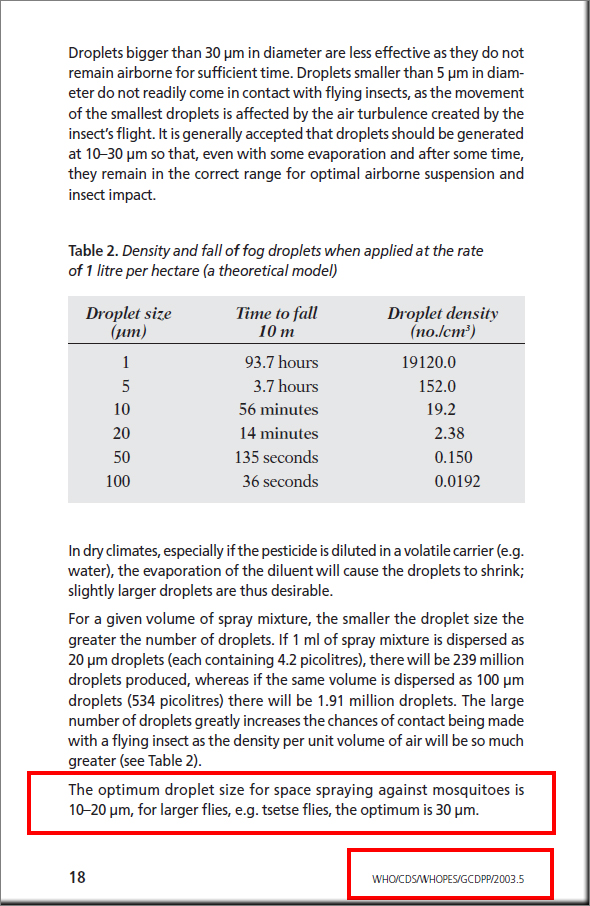

What should be the droplet size according to the target pest?

For the control of small flying insects like mosquitoes, the World Health Organization (WHO) has set a standard that the diameter of particles sprayed using the cold fogging method should be at most 20 microns (µm). The main purpose of this approach is to prolong the suspension time of sprayed droplets in the air, to increase their drift distance, and enhance the likelihood of effective biocidal particles reaching the target pests through contact.

For controlling black flies and other medium-sized insects, the WHO recommends using droplets of 30 microns (µm) in diameter via the ultra-low volume (ULV) spraying method. This method ensures the appropriate dosage of insecticide reaching the target flies effectively and eliminating medium size insects.

In the case of large pests such as locusts, ticks, and stink bugs, sprayed particle diameters should range between 50-100 microns (µm) using the Mist Blower method. This allows the application of biocidal chemicals in sufficient doses by matching the droplet size to the pest’s physical size, producing effective results. There are two main reasons for preferring droplet sizes of 50-100 microns (µm) in Mist Blower applications:

- ✔ Larger droplets are needed to effectively neutralize larger sized insects,

- ✔ In contact or systemic based spraying activity, to prevent the excessive drift of droplets in the wind. With Mist Blower method, insecticide can travel up to approximately 30 meters and settles within 90 seconds; reaching the ground as large droplets. Thus, even if a month passes after application, insects consuming insecticide residues on the ground are eliminated through residual effects.

This method is ideal for source control of large pests such as larvae, ticks, and cockroaches found in parks, gardens, garbage areas, water channels, and residential surroundings.

For the control of larvae, bacteria, and parasites, the Garden Sprayer method, which uses droplet sizes between 100-300 microns (µm), and systemic (residual) insecticides should be preferred. The machine is equipped with a 50-meter hose gun, allowing both short and long-range spraying. This enables effective spraying and disinfection applications in various areas and conditions. When the garden sprayer mode is activated, sprayed droplet diameters range between 100 and 300 microns. This feature offers a wide application scope, from systemic fly control in slaughterhouses to larval control in water paddles. It is also successfully used in disinfecting animal habitats from viruses and parasites, and effectively sanitizing garbage containers.

For successful and effective biocidal control, selecting appropriate particle sizes according to the pest species and strictly adhering to the application criteria set by the World Health Organization is essential. The WHO guide titled “A practitioner’s guide” provides detailed spraying criteria. Consulting expert specialists also contributes to successful biocidal control.

Incorrect micron sizes and non-compliant applications lead to failure in pest control, unnecessary loss of time, and wasted chemicals.

How should biocidal control be conducted?

What is the criterion for cold fogging?

The cold fogging method is defined by the World Health Organization with a droplet size range of 0-30 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 0-30 microns (µm). It is called “cold” because the process involves spraying as fog without using heat, by exposing the liquid to high air flow through a vortical type nozzle.

What is the ULV criterion?

The U.L.V. (Ultra Low Volume) method is defined by the World Health Organization with a droplet size range of 30-50 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 30-50 microns (µm). The liquid is sprayed at low volume without using heat, by exposing it to high air flow through a vortical type nozzle. The term Ultra Low Volume has been adopted in the literature as “low volume spraying.”

What is the Mist Blower criterion?

The Mist Blower method is defined by the World Health Organization with a droplet size range of 50-100 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 50-100 microns (µm). The liquid is sprayed at high volume without using heat. The term Mist Blower has been adopted in the literature as “high volume spraying.”

What is the Garden Sprayer criterion?

The Garden Sprayer method is defined by the World Health Organization with a droplet size range of 100-300 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 100-300 microns (µm). The liquid is sprayed at high volume without using heat. The term Garden Sprayer has been adopted in the literature as “handgun spraying.”

What is the Thermal Fogging criterion?

The Thermal Fogging method is defined by the World Health Organization with a droplet size range of 1-100 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 1-100 microns (µm). The liquid chemical is vaporized at a high temperature (400°C) and then sprayed as a dense fog (aerosol) cloud when it comes into contact with cold air. The sprayed particles are not transparent like in water-based spraying but appear as dense white smoke. The thermal fogging method does not burn the chemical or reduce its effectiveness. On the contrary, it provides an application that is 12 times more effective and efficient compared to water-based spraying. But because it obstructs visibility in traffic, its use on highways requires permission from local authorities. However, it is not subject to permission in private properties, rural areas, and residential neighborhoods. The term Thermal Fogging is known in the literature as “oil-based spraying.”

Technical Information

Additional information

| Engine | 10 Hp Briggs & Stratton, 306cc, gasoline, 1 cylinder, 4 stroke, air cooled, electric started |

|---|---|

| Pump | Positive displacement gear pump |

| Engine Fuel Tank | 5.3 L, steel, gasoline, approx. consumption 1.3 L/h |

| Chemical Tank | 200 L, stainless steel |

| Oil Burner Fuel Tank | 60 L, stainless steel, diesel, approx. consumption 8.5 L/h |

| Chemical Consumption | 50~500 L/h (Adjustable) |

| Battery Type | 12 V, 60 Ah |

| Spray Droplet Sizes | 1~100 µm (Adjustable) |

| Remote Control | 6 m cable, remote control on/off, engine start/stop, heating chamber on/off, fog on/off, |

| Air Velocity At Nozzle | 68 m/s |

| Noise Level | 84 dB(A) |

| Weight | Empty 210 Kg, Full 475 Kg, Shipping weight 310 Kg (without tank) |

| Dimensions | 89x201x80 cm (with nozzle), Shipping dimensions 96x151x99 cm (W,L,H) (without tank) |

| Origin | Made in Turkey |

| Warranty | 2 years |

| MOQ | 1 unit |

Reviews

There are no reviews yet.