ULV2000

ULV Sprayer and Mist Sprayer Machine

Documents18 HP USA-made engine equipped with a roots-type blower.

It comes with a 100-liter ULV tank and a 200-liter pulverizer tank.

The ULV and Pulverizer systems can be detached from each other and reassembled.

Capabilities:

✔ 15 µm Cold Fogging

✔ 30 µm ULV

✔ 55 µm Mist Blower

✔ 180 µm Garden Pulverizer

(Can be used efficiently in 4 different application areas.)

Description

Description

The vehicle-mounted ULV2000 model is a versatile and combined spraying machine that provides effective control in 4 different application areas. It features both a garden pulverizer (high-volume spraying) for residual chemical applications and cold fogging (low-volume spraying) for contact-effect chemical applications.

This model comes with a 100-liter ULV chemical tank and a separate 200-liter pulverizer chemical tank. The ULV and pulverizer units can be detached from each other or reassembled as desired. They can be used combined on a single vehicle or as two separate machines on two different vehicles. The chassis of the ULV machine and the garden pulverizer machine are independent from each other.

The ULV and garden pulverizer engines are Vanguard-Briggs Stratton brand, made in the USA, and are of the highest quality. The pulverizer pump and pressure regulator are Comet brand, Italian origin. The electric valves for chemical flow control are CEME brand, also Italian origin. In short, all components used in the machine are selected from the highest quality parts.

✅ Enables spraying 15 µm (cold fogging) and 30 µm ULV water-based chemicals for open-area treatment of flying winged pests such as mosquitoes and houseflies,

✅ Sprays 55 µm droplets in parks and gardens (by increasing flow rate) to extend settling time and treat ticks and similar crawling pests on grass,

✅ Provides access to hard-to-reach areas with its 50-meter hose and spray gun and enables residual chemical spraying of trash containers,

✅ A multifunctional combined spraying machine that easily performs spraying in slaughterhouses, riverbeds, wastewater treatment plants, building entrances and interiors, water paddles containing larvae, animal shelters, livestock production facilities, and garbage collection and storage areas.

The ULV2000 model operates according to 4 different spraying criteria: Cold fogging (0–30 µm), ULV (30–50 µm), Mist Blower (50–100 µm), and Garden Pulverizer (100–300 µm). This all-in-one spraying machine is ideal for a variety of pest control tasks: it combats winged insects like mosquitoes, houseflies, and midges with its ULV nozzle; targets ticks in parks and gardens using a 50-meter hose and spray gun; and applies Agita residual-effect chemicals in slaughterhouses, animal shelters, or waste areas, providing up to 60 days of effectiveness.

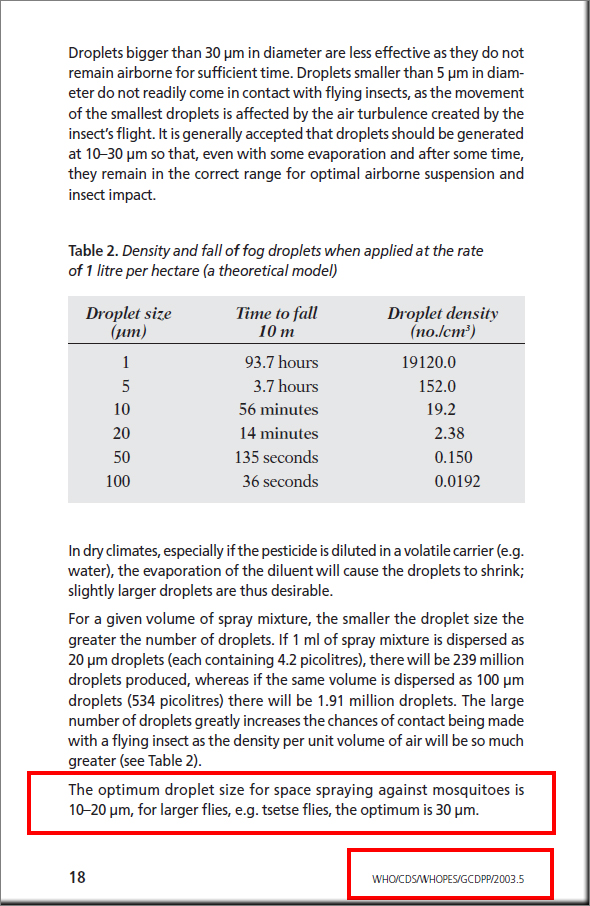

It is necessary to spray with droplet sizes suitable for the body size of the target pest. The World Health Organization (WHO) standard for mosquito adult (winged) control is a maximum droplet size of 20 µm. For houseflies, 30 µm; for ticks and larvae, larger droplets are required.

Advantages:

✔ It has one main regulator that adjusts the flow rate and micron size of all four nozzles. Additionally, each nozzle has an independent sub-regulator. The droplet size of all nozzles can be set simultaneously by the main regulator, or individually by the sub-regulators to spray different micron sizes. For example, the two nozzles on the right can be set to 30 µm for housefly control, and the two on the left can be set to 20 µm for mosquito control. Simultaneous control of pests of different sizes saves time and chemical costs.

✔ The nozzles can be manually rotated to the desired position. They allow 360° horizontal and 360° vertical rotation. All nozzles can be rotated simultaneously from the base and independently rotated left or right 360°. This provides a wider spray coverage, helping contact-effect chemicals more easily reach target pests and improving spraying efficiency.

✔ Equipped with a roots-type blower air pump. This positive displacement pump with two lobes is the longest-lasting and highest-performing blower used in vehicle-mounted ULV devices, capable of spraying at the smallest droplet sizes. Centrifugal pumps’ impellers tend to break, and motors in machines made with vacuum cleaner motors powered by generators burn out or deform quickly. Users aiming for minimal risk of failure and highest performance in vehicle-mounted ULV devices should always prefer machines equipped with roots-type blowers.

✔ The machine has a 2-year warranty against manufacturing defects and a 10-year spare parts availability and paid service guarantee.

✔ Chassis dimensions fit all double-cab vehicles.

✔ Licensed by the Republic of Turkey Ministry of Agriculture and Forestry.

✔ Optional 2-nozzle head available.

Frequently Asked Questions ;

What should be considered when purchasing a spraying machine?

When purchasing a spraying machine, the primary criterion is the uninterrupted continuation of periodic spraying activities. For example, mosquito control is generally carried out in 8-day cycles, and during this period, daily spraying must be done regularly considering the larval stage. Since the exact timing of larval deposition from previous mosquitoes cannot be known, the entire population is controlled by daily spraying for the first 8 days. Then, control is maintained with repeated periodic spraying every 8 days. This approach ensures significant savings in biocidal chemical consumption, effectively controlling the entire population.

However, if the spraying machine frequently breaks down, this routine is disrupted, and spraying activities must be restarted daily from scratch. This causes significant losses in both time and chemical costs.

Therefore, when choosing a spraying machine, instead of focusing solely on price-performance ratio; robust, durable, low-risk of break, simple, and purpose-appropriate machines should be preferred. Additionally, purchasing from manufacturers with a proven track record of easily and promptly supplying spare parts and providing after-sales support will be far more efficient in the long run.

In biocidal control, spraying machines are typically purchased once and used for about 10 years. However, biocidal chemicals must be regularly supplied every season for many years. Therefore, the correct equipment choice directly impacts chemical costs in the long term. To save on chemical use and conduct effective control, machines that can spray chemicals at the micron size most suitable for the target pest, have minimal risk of breakdown, and are made with quality components should be preferred. Such machines provide significant savings in labor, time, and chemical consumption, yielding successful biocidal control results in the long term.

What should be the droplet size according to the target pest?

For the control of small flying insects like mosquitoes, the World Health Organization (WHO) has set a standard that the diameter of particles sprayed using the cold fogging method should be at most 20 microns (µm). The main purpose of this approach is to prolong the suspension time of sprayed droplets in the air, to increase their drift distance, and enhance the likelihood of effective biocidal particles reaching the target pests through contact.

For controlling black flies and other medium-sized insects, the WHO recommends using droplets of 30 microns (µm) in diameter via the ultra-low volume (ULV) spraying method. This method ensures the appropriate dosage of insecticide reaching the target flies effectively and eliminating medium size insects.

In the case of large pests such as locusts, ticks, and stink bugs, sprayed particle diameters should range between 50-100 microns (µm) using the Mist Blower method. This allows the application of biocidal chemicals in sufficient doses by matching the droplet size to the pest’s physical size, producing effective results. There are two main reasons for preferring droplet sizes of 50-100 microns (µm) in Mist Blower applications:

- ✔ Larger droplets are needed to effectively neutralize larger sized insects,

- ✔ In contact or systemic based spraying activity, to prevent the excessive drift of droplets in the wind. With Mist Blower method, insecticide can travel up to approximately 30 meters and settles within 90 seconds; reaching the ground as large droplets. Thus, even if a month passes after application, insects consuming insecticide residues on the ground are eliminated through residual effects.

This method is ideal for source control of large pests such as larvae, ticks, and cockroaches found in parks, gardens, garbage areas, water channels, and residential surroundings.

For the control of larvae, bacteria, and parasites, the Garden Sprayer method, which uses droplet sizes between 100-300 microns (µm), and systemic (residual) insecticides should be preferred. The machine is equipped with a 50-meter hose gun, allowing both short and long-range spraying. This enables effective spraying and disinfection applications in various areas and conditions. When the garden sprayer mode is activated, sprayed droplet diameters range between 100 and 300 microns. This feature offers a wide application scope, from systemic fly control in slaughterhouses to larval control in water paddles. It is also successfully used in disinfecting animal habitats from viruses and parasites, and effectively sanitizing garbage containers.

For successful and effective biocidal control, selecting appropriate particle sizes according to the pest species and strictly adhering to the application criteria set by the World Health Organization is essential. The WHO guide titled “A practitioner’s guide” provides detailed spraying criteria. Consulting expert specialists also contributes to successful biocidal control.

Incorrect micron sizes and non-compliant applications lead to failure in pest control, unnecessary loss of time, and wasted chemicals.

How should biocidal control be conducted?

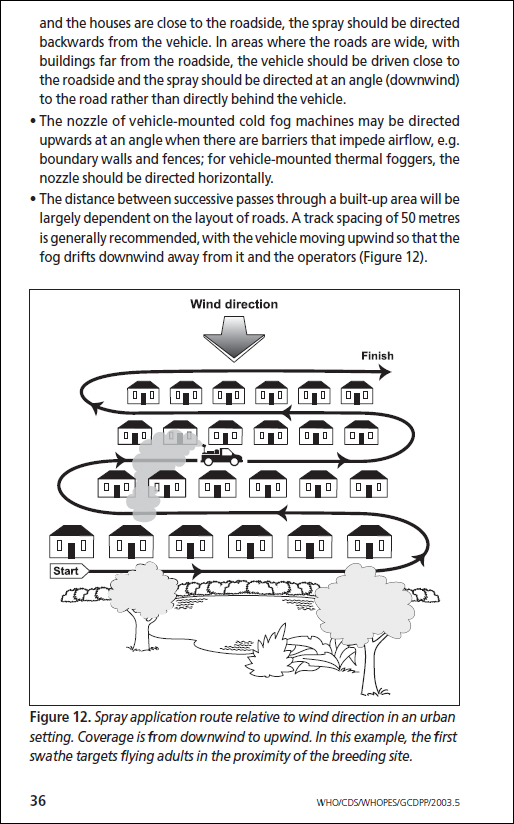

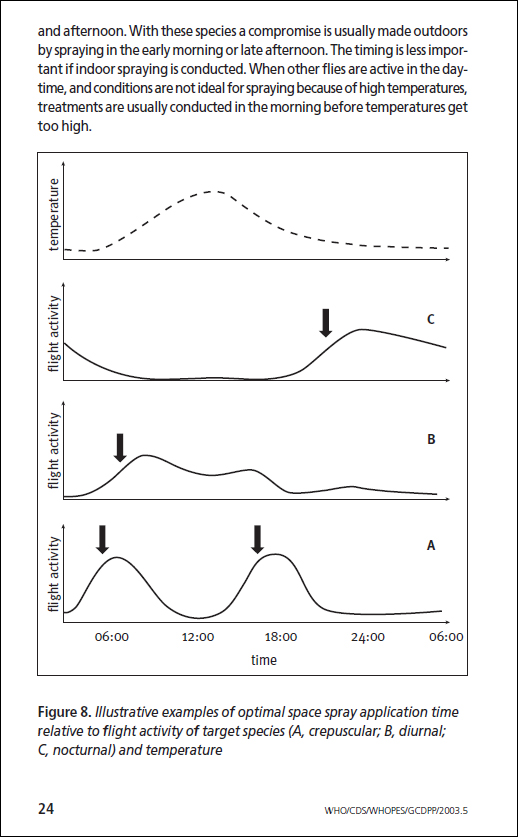

Wind direction, wind speed, air temperature, high pressure, low pressure, and other atmospheric conditions directly affect spraying activities. In this context, detailed spraying criteria can be found in the World Health Organization (WHO) guide titled “A practitioner’s guide.” Additionally, consulting expert specialists in the field will ensure successful biocidal control.

What is the criterion for cold fogging?

The cold fogging method is defined by the World Health Organization with a droplet size range of 0-30 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 0-30 microns (µm). It is called “cold” because the process involves spraying as fog without using heat, by exposing the liquid to high air flow through a vortical type nozzle.

What is the ULV criterion?

The U.L.V. (Ultra Low Volume) method is defined by the World Health Organization with a droplet size range of 30-50 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 30-50 microns (µm). The liquid is sprayed at low volume without using heat, by exposing it to high air flow through a vortical type nozzle. The term Ultra Low Volume has been adopted in the literature as “low volume spraying.”

What is the Mist Blower criterion?

The Mist Blower method is defined by the World Health Organization with a droplet size range of 50-100 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 50-100 microns (µm). The liquid is sprayed at high volume without using heat. The term Mist Blower has been adopted in the literature as “high volume spraying.”

What is the Garden Sprayer criterion?

The Garden Sprayer method is defined by the World Health Organization with a droplet size range of 100-300 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 100-300 microns (µm). The liquid is sprayed at high volume without using heat. The term Garden Sprayer has been adopted in the literature as “handgun spraying.”

What is the Thermal Fogging criterion?

The Thermal Fogging method is defined by the World Health Organization with a droplet size range of 1-100 microns (µm). In this method, the chemical substance in liquid form is sprayed as droplets sized 1-100 microns (µm). The liquid chemical is vaporized at a high temperature (400°C) and then sprayed as a dense fog (aerosol) cloud when it comes into contact with cold air. The sprayed particles are not transparent like in water-based spraying but appear as dense white smoke. The thermal fogging method does not burn the chemical or reduce its effectiveness. On the contrary, it provides an application that is 12 times more effective and efficient compared to water-based spraying. But because it obstructs visibility in traffic, its use on highways requires permission from local authorities. However, it is not subject to permission in private properties, rural areas, and residential neighborhoods. The term Thermal Fogging is known in the literature as “oil-based spraying.”

Technical Information

Additional information

| Engine (A) | 18 Hp Briggs & Stratton, 570cc, gasoline, 2 cylinders, 4 stroke, air cooled, electric started |

|---|---|

| Pump (A) | Roots type air blower, 2 lobes, positive displacement rotary type, 400 cfm, 3600 rpm |

| Engine (B) | 6,5 Hp Briggs & Stratton, 208cc, gasoline, 1 cylinder, 4 stroke, air cooled, electric started |

| Pump (B) | 3 Diaphragms, 40 bar, 25 L/min, 550 rpm (Comet APS31, made in Italy) |

| Connection Type (A+B) | V belt for ULV (A), Direct drive with hollow shaft gearbox for hydraulic sprayer (B) |

| Nozzle (A) | 4 nozzles, 360° |

| Nozzle (B) | 50 m long high pressure resistant hose, 1.8 mm and 2.5 mm orifices |

| Spray Droplet Sizes (A+B) | 15, 30, 55 µm for ULV (A), 180, 214 µm for hydraulic sprayer (B) (Adjustable) |

| Chemical Tank (A) | 100 L, HDPE, consumption 0~60 L/h for (A) |

| Chemical Tank (B) | 200 L, Polyester, consumption 156~ 264 L/h for (B) |

| Cleaning Tank (A) | 10 L, HDPE |

| Fuel Tank (A) | 40 L, HDPE, approx. consumption 2.5 L/h |

| Fuel Tank (B) | 3.1 L, steel, approx. consumption 1.1 L/h |

| Remote Control (A) | 6 m cable, remote control on/off, engine start/stop, ulv spraying on/off, flush on/off |

| Air Velocity At Nozzle (A) | 172 m/s |

| Noise Level (A+B) | 93.5 dB(A) |

| Battery Type (A+B) | 12 V, 60 Ah (Both systems have separate batteries) |

| Weight | Empty 360 Kg, Full 713 Kg, Shipping weight 650 Kg |

| Dimensions | 140x140x120 cm, Shipping dimensions 150x150x140 cm (W,L,H) |

| Extra Options (A) | 2 nozzles, Rotating automatic nozzle with remote control operation |

| Origin | Made in Turkey |

| Warranty | 2 years |

| MOQ | 1 unit |

Reviews

There are no reviews yet.