If temperatures in open fields are expected to drop to a maximum of –4°C, the vapor of diesel fuel alone or AV fogging oil alone can provide effective protection. If temperatures are expected to fall below –4°C, better results can be achieved in open fields by using a combined application of vegetable glycerin and AV fogging oil, which helps save more crops.

At temperatures lower than –4°C, during the night, first vegetable glycerin vapor must be sprayed over the field benefitting from its antifreeze properties. Vegetable glycerin vapor will form an invisible oil film around the flowers. It will penetrate between the two hydrogen bonds in water molecules and, thanks to its antifreeze properties, will delay and prevent ice formation.

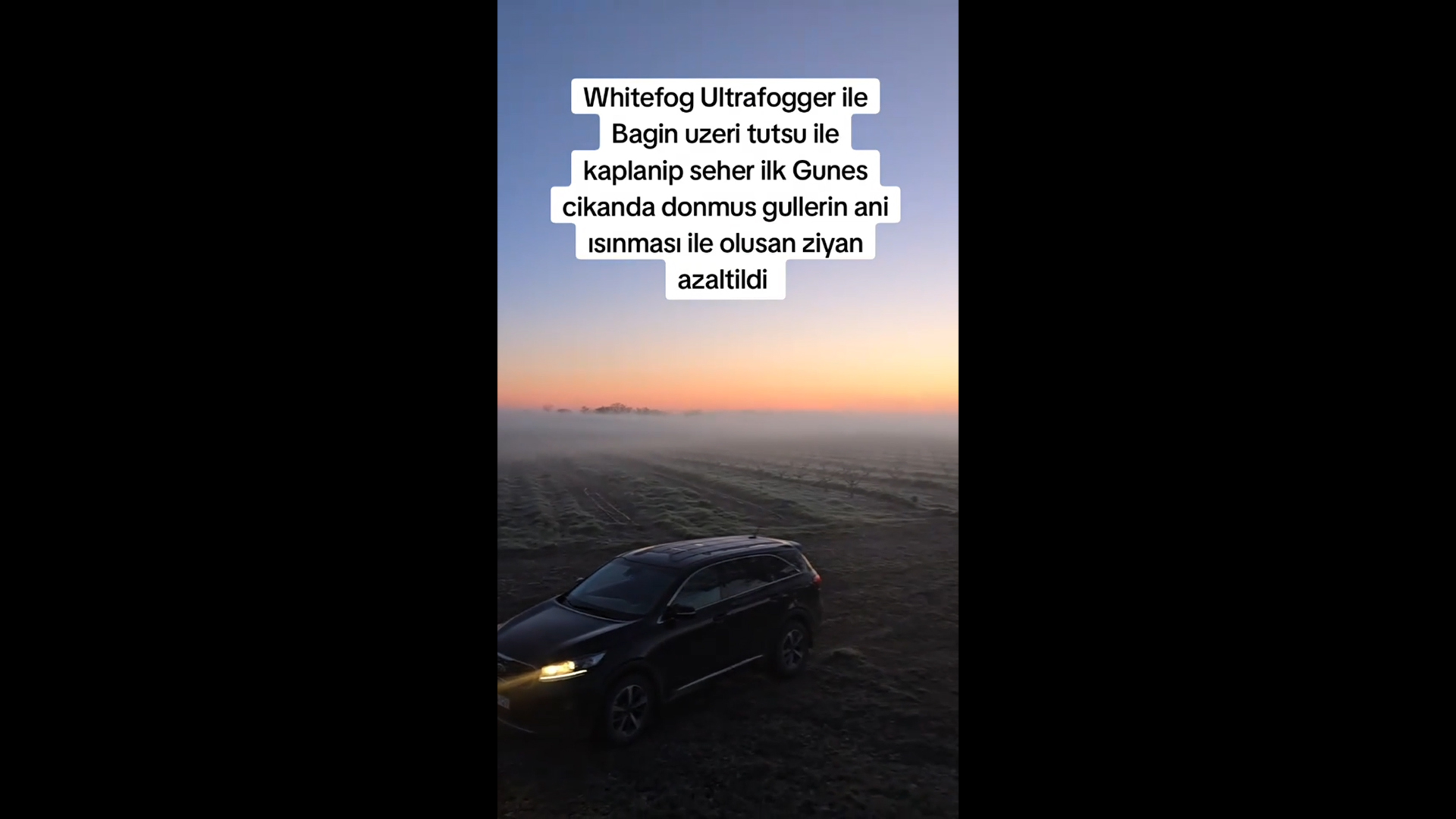

Then, at sunrise, we recommend spraying AV fogging oil vapor. The artificial cloud curtain should be bright white, dense, and thick, blocking as much of the sun’s red radiation as possible. The red light emitted by the sun at sunrise (700 nm wavelength) is the longest and most intense radiation wavelength. The term radiation frost comes from this phenomenon. Even if the flowers have managed to stand the cold during the night, the greatest damage is caused by the red light emitted by the sun. This is called conduction damage (heat transfer). Cold flowers, lightly covered with ice, are suddenly exposed to red light (high heat), causing them to burn rapidly, their surfaces to be damaged, and their cell sap to be lost.

If, during the night, the flowers are coated with a thin oil film of antifreeze vegetable glycerin, and during radiation frost at sunrise in windless, cloudless conditions a dense artificial cloud curtain is created using AV fogging oil (aviation oil) or diesel, a protective artificial atmosphere above the plants is formed and conduction-based frost damage does not occur.

A simple example of conduction damage is as follows: place a fish in a hot pan without adding oil. Due to rapid heat transfer (conduction), the fish will quickly burn and stick to the pan, damaging its surface. If oil is added, a thin oil layer forms between the hot pan and the cold fish, preventing direct heat contact and delaying burning.

During agricultural frost, the surface of the flowers is very cold. The thin oil layer formed by vegetable glycerin around the flowers prevents the high heat from the rising sun from being transmitted directly to them. The oil layer acts as a delay between the flowers and the sunlight. This antifreeze layer slows the transfer of heat to the flower surface and prevents damage from sudden heat transfer (conduction). The reason for choosing the whitest smoke and forming a thick artificial cloud curtain at sunrise is to delay sunlight from reaching the flowers as much as possible.

IN SUMMARY:

Vegetable glycerin sprayed during the night creates an antifreeze effect on the flowers, delaying cooling and freezing as much as possible. At sunrise, AV fogging oil (aviation oil) or diesel vapor, with its bright white smoke, provides a reflective effect that delays the sun’s heat from reaching the flowers too quickly. With this technique, both the cooling phase and the warming phase are slowed in a controlled manner. By delaying both processes, a double protective effect is achieved, minimizing radiation frost damage and maximizing protection.

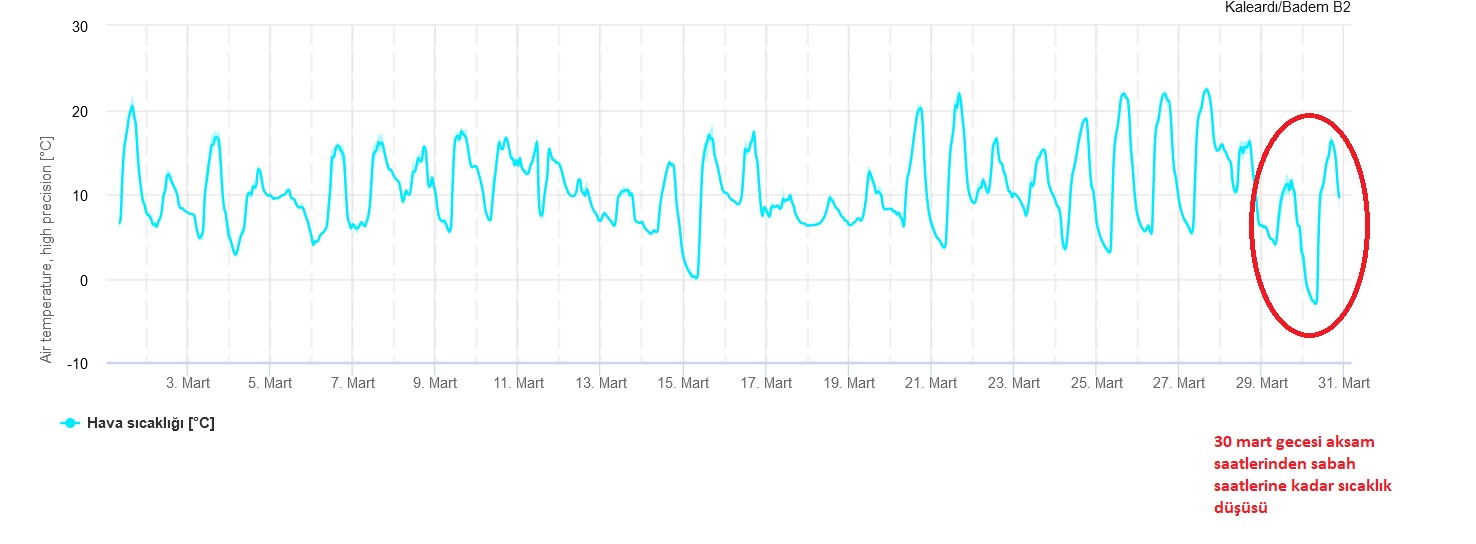

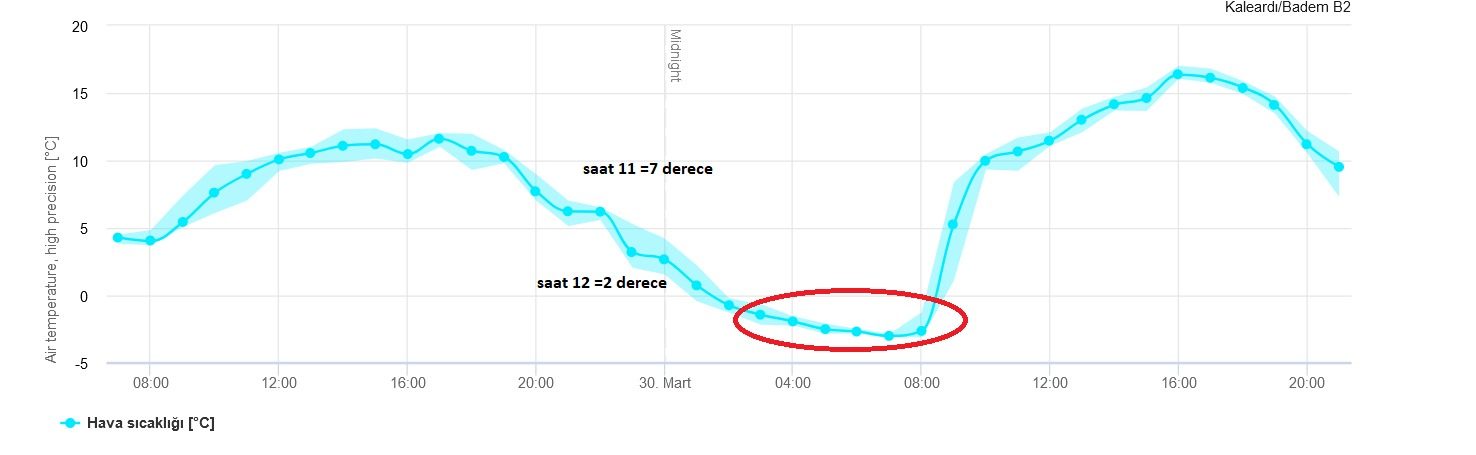

In above graphic, we see that in the night of March 30th at 22:00, the temperature was 7 degrees and dropped to 2/3 degrees by 23:00 and 00:00. Such a sharp drop in about 1 hour is a warning of frost.

In above graphic, we see that in the night of March 30th at 22:00, the temperature was 7 degrees and dropped to 2/3 degrees by 23:00 and 00:00. Such a sharp drop in about 1 hour is a warning of frost.

Reviews

There are no reviews yet.